"demystifying the Composition: What Are 3D Printers Made Of?"

Introduction

In recent years, 3D printing technology has made significant strides, finding applications in a variety of fields - from healthcare and aerospace to fashion and food crafting. But behind these groundbreaking applications lies a fundamental question - what are 3D printers made of? This article aims to unravel the mystery behind the composition of 3D printers, delve into the impact of these materials on their performance, and explore the environmental considerations and future prospects of this revolutionary technology.

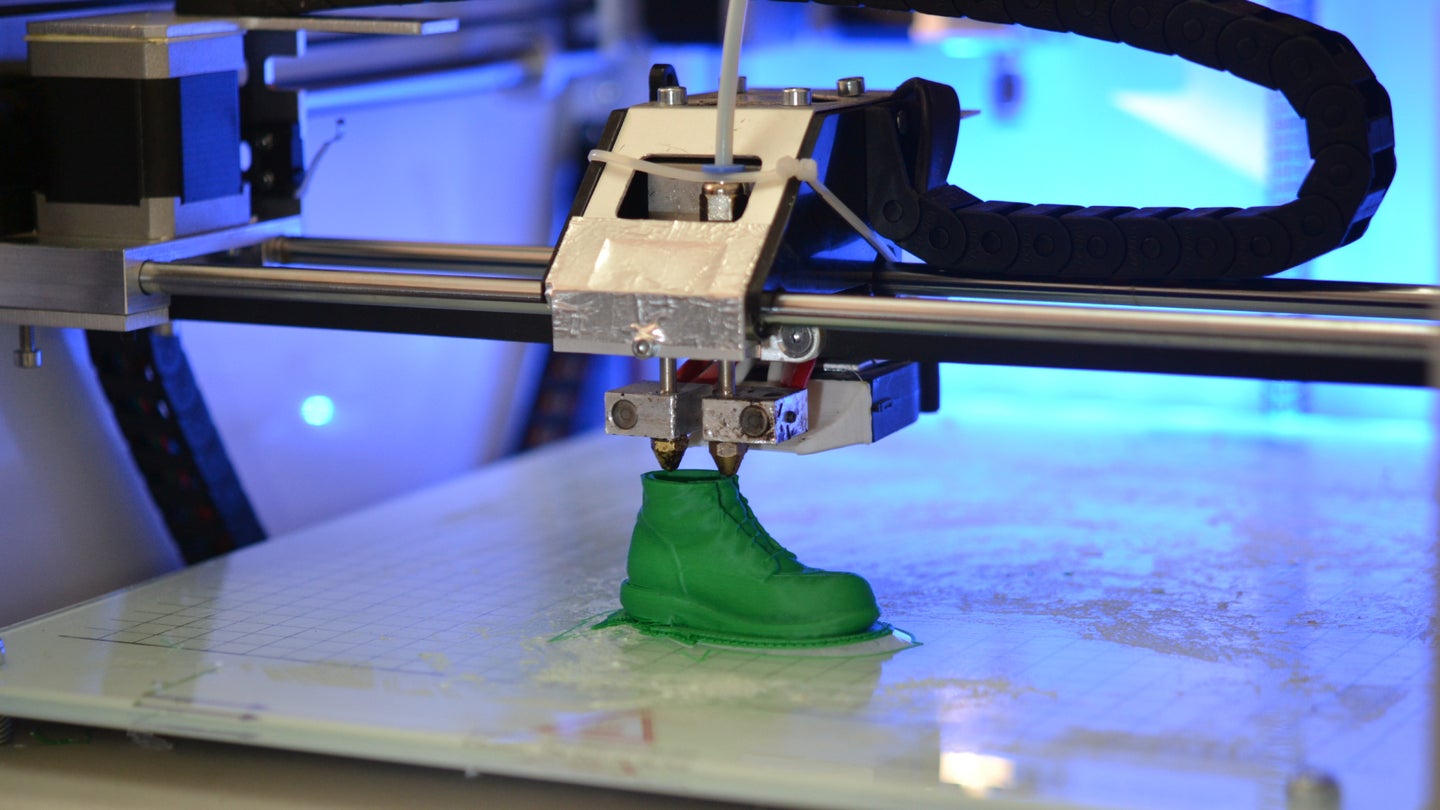

What Is 3D Printing and How Does It Work?

3D printing, recognized as additive manufacturing, is a groundbreaking technology that facilitates the production of three-dimensional structures. The creation of these structures is carried out by accumulating materials layer by layer, strictly following a digital blueprint.

Here's a step-by-step guide to how it works:

1. Designing the Model: The process initiates with the production of a digital design using Computer-Aided Design (CAD) software. This design acts as the virtual blueprint for the 3D object.

2. Slicing the Design: This digital model is then sliced into numerous thin horizontal sections. The 3D printer uses these slices to build the object thoroughly and accurately.

3. Building the Object: The chosen material is subjected to be heated until it reaches a semi-fluid state. Then, it is precisely deposited layer by layer, following the object's digital slices.

4. Cooling: Finally, each layer cools and solidifies, resulting in a finished three-dimensional object, meticulously matching its digital counterpart.

In essence, 3D printing is like assembling a multi-layered jigsaw puzzle, except that here, the layers are manufactured, not merely put together!

What Materials Are Used to Construct 3D Printers?

Understanding the building blocks of 3D printers can provide a fascinating insight into how they function, and how various materials can impact the overall outcome.

The Vital Presence of Metals in 3D Printers

3D Printers often engage various metals in their construction, primarily due to their strength, stability and durability attributes. These are particularly prevalent in:

- Printer's Frame: Generally made of heavy-duty metals such as steel or aluminum, these frames provide stability and prevent vibrations that could compromise precision.

- Moving Parts: Components like print head and bearings, often fabricated from metal due to its heat resistance and robustness.

- Hardware: Other hardware components, including screws and brackets, are typically made of metal for their strength and longevity.

Plastics- The Backbone of 3D Printers

Notwithstanding metals, plastic components are also greatly involved in the making of 3D printers:

- Encasement: The exterior parts of the printer like the casing or cover are mostly made of hard plastics for a lightweight yet sturdy structure.

- Filaments: Most common print material in desktop 3D printers are plastic polymers, like ABS (Acrylonitrile Butadiene Styrene) or PLA (Polylactic Acid).

Unconventional Ingredients for 3D Printers: Ceramics, Edibles and Beyond

Besides the standard metals and plastics, some 3D printers also incorporate more unusual materials:

- Ceramics: For specialty printers used to create complex ceramic objects.

- Food: Certain printers can work with ingredients such as chocolate or dough to create intricately designed edible goods.

- Biomaterials: Researchers are exploring the use of living cells in 3D bio-printers, revolutionizing fields like medicine and tissue engineering.

Embracing this varied inventory of materials allows 3D printers to serve an extensive array of sectors, and utilize their unique properties for specialized applications.

How Do the Used Materials Impact the Efficiency and Quality of 3D Printing?

The materials that make up the 3D printer itself hold substantial sway over its overall efficiency and the caliber of the prints it produces. Here, we delve into some of the key ways these materials influence the process:

Reinforced Rigidity Through Metal Elements

Metal pieces, often used to construct the 3D printer's frame and print bed, contribute to the machine's rigidity and stability. These aspects are essential for achieving precise, high-quality prints. In fact:

• High-quality metals, such as stainless steel and aluminum, enhance the printer's durability and lifespan.

Plastic Components Paving the Path for Perfection

Plastics like ABS and PLA frequently make up the extruder assembly, which handles the deposition of the print material:

• The type and quality of these plastic materials can determine the layer deposition's smoothness, greatly influencing the finished product's quality.

The Unseen Potential of Unconventional Materials

3D printers aren't limited to just standard materials; certain models incorporate ceramics, woods, and even foods like chocolate:

• Though such unconventional materials may not inherently affect printer efficiency, their specific applications — combined with the printer design — may produce unique, specialized items and expand the horizons of 3D printing.

In summary, the material components of a 3D printer and their quality significantly shape the machine's performance and the resulting 3D-printed objects. This revelation underscores the importance of carefully selecting printers built with high-quality materials, especially meant for applications requiring superior precision and durability.

What Are the Environmental Impact and Sustainability Concerns Related to These Materials?

3D printing technology, while transformative and innovative, has its share of environmental repercussions and sustainability challenges. These primarily stem from the materials used in creating both the printers and the end-products. Here's an overview of some key considerations:

- Plastic Consumption: Traditional 3D printers often use non-biodegradable plastic types like ABS (Acrylonitrile Butadiene Styrene), adding to the growing concern of plastic pollution. Globally, tens of thousands of tons of ABS are consumed by 3D printers annually, contributing significantly to landfill waste.

- Metal Usage: The production and disposal processes for metals used in 3D printer construction can contribute to high carbon emissions. For instance, the steel industry accounts for approximately 7% of global CO2 emissions.

- Future Direction in Sustainability: However, offsetting these concerns is a growing emphasis on more environmentally friendly materials. For instance, many 3D printers now use PLA (Polylactic Acid), a type of biobased and biodegradable plastic.

- Research in Recyclability: There's also a considerable amount of research in progress on recycling used filaments and integrating waste materials into the printing process. If successful, this could substantially lower the environmental impact of 3D printing.

Despite these environmental challenges, the embracing of more sustainable materials and waste minimization strategies is expected to improve the 3D printing industry's ecological footprint. These concerted efforts signal a commitment to balance the inspirational potential of this technology with the essential need for environmental responsibility.

What Is the Future of 3D Printers Based on Current Material Use?

3D printing technology continues to evolve at an unprecedented rate, with changes in the materials used shaping its future direction. So what could the landscape of 3D printers potentially look like given the current trends in the materials employed? We delve into the possibilities.

A Greater Push Towards Sustainability

The industry has already begun recognizing the environmental responsibility that comes with 3D printing. Therefore, the primary shift in the future is likely to be about favoring more sustainable materials like:

- Polylactic Acid (PLA): A bio-degradable thermoplastic derived from renewable resources like cornstarch or sugarcane. This green shift away from conventional non-biodegradable plastic materials like ABS could significantly decrease plastic waste.

- Eco-friendly Metals: Metals with a smaller carbon footprint during production and disposal, thus contributing to reduced CO2 emissions.

Innovative Recycling Initiatives: Reuse and Repurpose

To further mitigate the environmental impact, future emphasis might be on initiatives such as:

- Reusing Waste: The industry might continue to explore methods to convert the waste material or used filaments into a suitable form that can be reused in the printers.

- Repurposing Old Prints: Thereby reducing the plastic and metal waste produced, and carving a path to a more circular economy in 3D printing.

Unveiling Exciting Possibilities with Unconventional Materials

As we continue to push the boundaries of what's possible with 3D printing, we might witness increased usage of unconventional materials. This could include:

- Edible Materials: Like chocolate or sugar, leading to more culinary applications.

- Wood or Ceramics: Offering a broader range of potential creations, from decorative pieces to functional items like crockery or furniture.

In conclusion, the future of 3D printing based on current material use appears to be steering towards sustainability, characterized by environmental consciousness, innovative recycling initiatives, and an exploration of unconventional materials. These exciting possibilities could revolutionise the 3D printing realm, offering not just a wider range of applications, but also an opportunity to further integrate this technology while leaving a smaller environmental footprint.

Conclusion

Despite the existing environmental challenges, 3D printing exhibits tremendous promise. With continuous innovation both in the materials employed and their application, 3D printing could soon turn into a mainstay of modern manufacturing, enabling more efficient and personalized production while leaving a smaller environmental footprint.

Related FAQs about what are 3d printers made of

What are the most commonly used materials in 3D Printers?

The most common materials used in constructing 3D printers are metals and plastics. Metals like steel or aluminum are typically used for the printer's frame, while plastics like ABS (Acrylonitrile Butadiene Styrene) or PLA (Polylactic Acid) are commonly used as filaments for printing.

How do the materials used in 3D printers impact the quality of the printed object?

The materials used in 3D printers, particularly the filament material, significantly impact the print quality. Factors such as the type, quality, and temperature of the filament can determine the smoothness of layer deposition and the sturdiness of the finished product.

Are there any eco-friendly alternatives to the currently used materials in 3D printing?

Definitely. Many printers are now using PLA (Polylactic Acid), a type of biobased and biodegradable plastic. Researchers are also exploring ways to recycle used filaments and integrate waste materials into the printing process to reduce environmental impact.